Summary: Automated warehouses utilize specialized warehouse management software to automate repetitive tasks and minimize labour costs. Keep on reading to find out about top software you can consider for warehouse automation.

Warehouses are an important aspect of supply chain operations as they serve as a link between goods production and distribution. However, many businesses manage these operations manually and that makes it challenging to meet their consumers’ demands on time.

In that scenario, automating your warehouse can solve your problem. By using warehouse automation software and technologies, you can manage inventory levels, streamline order fulfillment and shipment, and handle return orders.

In this article, you will learn more about warehouse automation software and the types of technologies you can use to automate warehouse operations.

What Is Warehouse Automation?

Warehouse automation is the procedure of automating the inventory’s movement into, within, or outside the warehouses to customers via technologies like software and robots.

The main purpose of this automation is to complete tasks with minimal human assistance and create a fully automated warehouse. With automation, businesses can avoid labor-intensive tasks and get rid of manual data entry.

Types of Warehouse Automation Technology

There are several types of warehouse automation technologies to automate key tasks like item picking, reloading, packaging, etc.

Some of the most popular technologies include Goods-to-Person, Automated Storage and Retrieval Systems, Automatic Guided Vehicles, Autonomous Mobile Robots, Automated Sortation Systems, etc.

Let’s learn about these technologies in detail below:

- Goods-to-Person (GTP): It is a type of warehouse automation solution under which goods are brought to the person via fixed or Autonomous Mobile Robots (AMRs). These robots are in the form of conveyors, carousels, and vertical lifts.

- Automated Storage and Retrieval Systems: These are computer and robot aided systems to store and retrieve items in a particular space. Material-carrying vehicles, tote shuttles, mini-loaders, etc., are the ideal examples of AS and AR systems

- Automatic Guided Vehicles: These are programmable robots for transportation tasks that automatically navigate through warehouses with technologies like magnets, lasers, vision, etc.

- Autonomous Mobile Robots (AMRs): AMRs are robots that can comprehend and move within their environment independently. They utilize GPS systems to develop efficient routes in a specific warehouse.

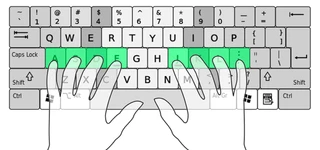

- Pick-to-Light and Put-to-Light Systems: These systems utilize mobile barcode scanning devices synced with digital light displays to guide warehouse pickers from where they need to pick and place the selected items. This will help warehouse pickers in reducing walking and item searching item.

Top 7 Warehouse Automation Software in India

Let’s look at some of the best software you can use to automate your warehouse operations and manage machines and robots installed at your facility.

These solutions are listed along with their features, benefits, and limitations to help you choose the right warehouse automation software.

Softeon

Softeon is a warehouse management software used to streamline supply chain, logistics, inventory, and labour management operations.

By using this software, you can streamline tasks like order picking and shipping, inventory updating, parcel managing, etc. With its supply chain module, you can also manage and automate your supply chain operations.

Softeon Features

- Manages all inventory-related bills

- Manages and tracks labor’s schedule

- Offers slotting algorithm to track inventory movement

- Support inventory picking via voice

Pros and Cons of Softeon

- Softeon also came with a quality check control feature to ensure only the top-quality products are sent to customers.

- It integrates with EDI, ERP and financial software to manage product data.

- It does not provide a payment processing feature.

BrightPearl

BrightPearl warehouse management software helps streamline and automate warehouse operations for e-commerce, wholesale merchants, and retailers.

With this software, you can manage your order returns, accurately track inventory, automate order fulfilment, perform accurate inventory demand forecasting, etc. You can also manage POS and order shipment with BrightPearl.

Features of BrightPearl

- Quickly scans barcodes to track inventory

- Batches shipments together based on the preferred criteria

- Performs partial or full inventory count cycles

- Automatically reconciles deliveries and returns

- Automatically manages drop shipping, invoicing, order fulfillment, etc.

Pros and Cons of BrightPearl

- Provides built-in tools to forecast demand and automatically trigger purchase orders to maintain optimal stock levels.

- It also supports multi-location inventory tracking.

- Users have mentioned that the reported bugs are seldom acknowledged.

Symbotic

Symbotic provides robotic automation and warehouse logistics software to automate warehouse operations. It is designed to automate tasks in distribution centers, warehouses, and other industrial settings, with the goal of improving efficiency.

With its advanced robotic systems and machine learning capabilities, the warehouse robots can easily navigate and operate in warehouse environments.

Symbotic Features

- Offers advanced mobile robotics control

- Supports bot routing and sequencing

- Provides palletization algorithms to pack goods in pallets

- Analyzes real-time data to optimize item placement

Pros and Cons of Symbotic

- Provides accurate and up-to-date information on inventory levels, location, and status of each item within the warehouse.

- It also supports advanced orchestration.

- It has a huge upfront cost for hardware, software, and installation.

Zoho Inventory

Zoho Inventory is an online inventory management software designed for businesses to efficiently manage their stock, orders, and the overall inventory operations.

It provides features such as order tracking, multi-channel selling, warehouse management, and integration with other Zoho applications for comprehensive business process management.

Zoho Inventory Features

- Supports multi-warehouse management

- Updates product lists automatically

- Selects warehouse closest to customer’s location for timely pickup and delivery

- Tracks product transfer orders via serial number

- Generates accurate reports to get sale and purchase insights

Pros and Cons of Zoho Inventory

- Supports multi-channel product selling.

- Provides a mobile app to use the software on the go.

- Does not support integration with Shopify.

LOGIC ERP

LOGIC ERP Warehouse Management Software automates and streamlines warehouse management with features like space management, bin wise inventory management, multi-location inventory management, etc.

For automated storage and warehouse management, it supports multi-location inventory tracking, purchase orders and vendors management, serial number and lot tracking, items’ profile management, etc.

LOGIC ERP Features

- Verifies physical stock via RFID, mobile app, PDA, etc.

- Automatically allocates goods to the defined product category

- Allocates stock on bin-wise, based on the capacity calculation

- Creates a stock picking list for stock item retrieval

- Manages inventory in multiple warehouses locations

Pros and Cons of LOGIC ERP

- This warehouse management software provides a mobile app that helps with stock retrieval against the pick list.

- It also offers capacity management for stocks based on their units and volume.

- The interface of LOGIC ERP is quite complicated for beginners.

Oracle Fusion Cloud SCM

Oracle Fusion Cloud SCM (Supply Chain Management) is an integrated suite of applications offered by Oracle to streamline and enhance various operations of the supply chain.

It comes with features like inventory management, order fulfillment, procurement, logistics, and product demand planning. This warehouse automation software ensures real-time visibility, automation, and collaboration across the entire supply chain.

Features of Oracle Fusion Cloud SCM

- Provides real-time visibility into inventory levels

- Supports product demand forecasting and planning

- Optimizes transportation planning routes

- Manages product sourcing

- Stores and tracks supplier’s details

Pros and Cons of Oracle Fusion Cloud SCM

- The supplier registration procedure is quite easy with Oracle.

- It has a strong backend system to handle bulk data.

- It does not provide any open APIs for integration with other tools.

Wasp Inventory Management

Wasp Inventory Management software offers a centralized place to manage the procedure of ordering, receiving, and picking for both inventory and non-inventory items.

Some other features of this software include item tracking, barcode scanning, inventory transactions managing, etc.

Wasp Inventory Management Features

- Maintains accurate stock counts

- Streamlines product order procedures

- Manages purchase order requisitions

- Generates real-time inventory reports for data analysis

Pros and Cons of Wasp Inventory Management

- You can use this software to track inventory across multi-location warehouses.

- With it, you can gain deeper insights into your inventory data via advanced reporting tools.

- Its mobile app has lesser features than its desktop version.

Benefits of Warehouse Automation

There are several benefits of warehouse automation, such as efficiently managing labour, optimizing storage and handling costs, improving warehouse visibility, and also optimizing inventory levels.

- Increases Efficiency: Warehouse automation streamlines processes like inventory tracking and order fulfillment, reducing the time to complete tasks and achieving higher operational efficiency.

- Saves Costs: In the long run, automation can save costs through increased productivity, reduced labor costs, and minimized data errors.

- Improves Speed: Automated warehouse management software can perform tasks at a faster pace than manual labor, leading to quicker order processing and faster delivery.

- Improves Safety: Warehouse software can handle repetitive and potentially hazardous tasks like loading inventory items, thereby reducing the risk of workplace accidents and injuries.

- Provides Real-Time Data Visibility: Automation provides real-time data updates on inventory levels, order status, and other similar metrics, enabling better decision-making and inventory control.

- Improves Customer Satisfaction: It helps with faster order fulfillment along with improved inventory management. This contributes to higher customer satisfaction by meeting delivery expectations and reducing products shipment errors.

Warehouse Automation Best Practices

For proper warehouse automation, you should choose the right software and technology and perform continuous inventory cycle counts.

Moreover, you should also evaluate the warehouse design to select the right system or technology. Let’s find out some important practices that you can implement while automating your warehouse operations.

- Do a Thorough Warehouse Analysis: Conduct a comprehensive analysis of your warehouse operations to find areas where automation can bring the most benefits and reduce manual workload.

- Set Clear Objectives: Define clear and achievable goals for automation, whether it’s increasing efficiency, reducing errors, or improving order fulfillment speed. Only after setting objectives, you can choose suitable warehouse management software for automation.

- Consider Incremental Implementation: Consider applying a phased approach for warehouse automation rather than trying to automate everything at once. You can start with key processes to minimize disruptions.

- Consider Scalable Software: Consider buying scalable automation software that can scale with the growth of your business, allowing for easy expansion like adding more warehouses, employees, equipment or a new supply chain partnership.

- Train Your Employees: Provide proper training to your warehouse staff to effectively work alongside automated warehouse systems.

- Conduct Cost-Benefit Analysis: Regularly conduct the cost-benefit analysis. This will ensure that the warehouse automation investment aligns with business objectives and provides a positive return on investment.

Conclusion

Warehouse automation is a transformative force in logistics and supply chain management. Through the integration of advanced technologies such as robotics, artificial intelligence, software, and IoT devices, it has not only streamlined operational processes but has also enhanced efficiency, accuracy, and overall productivity.

Hence, automating warehouse operations is imperative for businesses to meet consumer expectations and manage the increasing order volume.

FAQ Related to Warehouse Automation

What is a storage and retrieval system?

An automated storage and retrieval system is a type of robotics that can pick up and store items in a particular place.

What is warehouse automation?

Warehouse automation is the procedure of automating inventory movement in and out of warehouses with software, systems, and robots.

What are the three levels of warehouse automation?

The three levels of warehouse automation include basic automation, partial automation, and complete automation.

How do you automate warehouse processes?

To automate your warehouse procedures, you can use a warehouse management system. With it, you can manage the functioning of robots, machines, and systems installed in your warehouse location.

What are some of the best automated warehouse systems?

Some of the best automated warehouse systems that you can use to run your warehouse include Softeon, Fortna, Symbotic, Swisslog, Zoho Inventory, LOGIC ERP, Oracle Fusion Cloud SCM, etc.

Varsha is an experienced content writer at Techjockey. She has been writing since 2021 and has covered several industries in her writing like fashion, technology, automobile, interior design, etc. Over the span of 1 year, she has written 100+ blogs focusing on security, finance, accounts, inventory, human resources,... Read more